With each passing year, new cars get more complicated and high-tech. The new higher power requirements associated with these advancements—along with ever-stricter emissions regulations—are why 48-volt electrical systems are spreading like wildfire, with experts expecting the tech to make its way into one-fifth of all cars sold globally by 2025. That’s a huge figure, but this technology isn’t exactly new. Here’s how it works.

I decided to contact two major automotive suppliers, Delphi and Continental, to get a better understanding of what these 48-volt systems do and why they’re just now becoming popular. It comes down to two reasons: first and foremost is helping cars meet emissions regulations, and the second is providing more power to the features buyers expect.

Lifting The Power Burden

Over the last decade or so, automakers have been replacing traditionally mechanically-driven components with more efficient parts like electric power steering racks, electric brake vacuum pumps and electric water pumps.

On top of that, especially in Europe, automakers have been adding in a ton of new infotainment options, and also driver-assist safety features like adaptive cruise control, lane keep assist, blind spot monitoring, etc. Plus, you’ve still got heated seats, heated steering wheels and heated windshields. Needless to say, standard 12-volt electrical systems are being stretched thin; so 48-volt systems are stepping in and help accommodate the need for more on-board power.

This is especially true on luxury cars. The Bentley Bentayga, for example, uses the 48-volt battery to drive an electric sway bar system for better handling, and Audi is using the pack to power an electric supercharger.

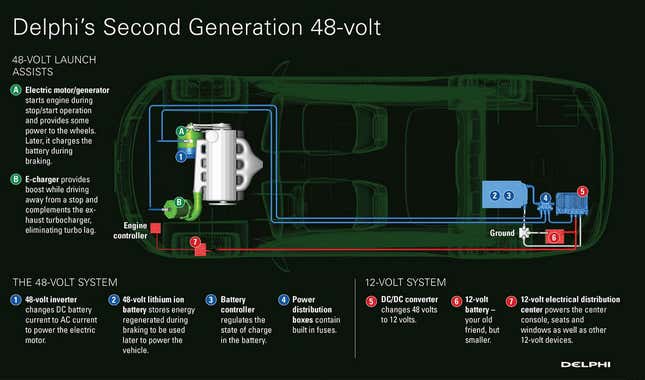

Delphi’s vice president of engineering, Mary Gustanski, told me the latter technology can be a huge improvement to vehicle launch capabilities. The company’s own “E-charger” on a Honda Civic spools up the vehicle’s turbo during a stop/start event and at low engine speeds to essentially eliminate turbo lag and smooth out low rpm torque deficiencies, provide up to a 25 percent increase in low end torque and 30 percent better acceleration.

So 48-volt systems can mean more electronic gizmos inside the car, but it can also mean more performance under the hood.

How It Works

Despite what you may have read about 48-volt systems, the 12-volt battery that powers all your car’s lights, engine accessories and infotainment, isn’t going anywhere anytime soon.

That’s because instead of replacing your current electrical architecture entirely (like the auto industry contemplated doing with 42-volt systems in the 1990s), upcoming 48-volt designs complement it in what is essentially a mild hybrid arrangement. In other words, a new electric motor and 48-volt battery are simply added onto the combustion engine and normal 12-volt battery, similar to what you might have found in General Motors’ BAS hybrids of the late 2000s like the Buick LaCrosse or Saturn Aura.

Similar to these older GM electrified powertrains, most new dual-voltage mild hybrid designs (like the 48V system in the Renault Scenic) consist of three main components: a Belt Alternator Starter (also called a Belt-driven Starter Generator or Motor Generator Unit, MGU), a DC-to-DC converter, and a higher voltage battery.

These three components are meant to easily adapt to electrical systems and packaging environments of regular, non-hybrid cars, with the MGU replacing a traditional alternator on the front end accessory drive, and the DC-DC converter and battery taking up a small amount of space in the trunk.

This makes 48-volt mild hybrids a relatively cheap, easy and lightweight way to get, as Gustanski told me, “50 to 70 percent of the benefit at 30 percent of the cost [of a full hybrid].” That 50-70 percent translates to fuel economy improvements of about 10 to 15 percent.

Continental agrees, saying its initial tests show a 13 percent fuel economy benefit in the NEDC drive cycle, but that real world fuel economy could increase by a whopping 21 percent—enormous gains for a simple and easily implemented system.

Lithium Ion Battery Pack And DC-To-DC Converter

On Continental and Delphi’s 48-volt systems, the battery is a lithium-ion unit about the size of a shoebox (the black box above). The sub-1 kWh battery pack sends juice to a small 12-volt lead-acid battery via a trunk-mounted DC-to-DC converter (the silver box with the fan), which steps down the voltage to power the car’s 12-volt accessories.

Why 48 volts for the bigger battery? Gustanski told me that it comes down to power and cost. A 48-volt battery can provide four times the on-board power of a 12-volt battery, which means it can be used to fire up a multitude of high-draw accessories like fans, pumps, electric power steering racks and compressors, which can now work more efficiently. In addition, there are benefits to wire-harness size and weight (presumably because of lower current draws through the wires at these higher voltages).

Gustanski admits that an even higher voltage battery could offer even more capability, but federal standards require costly shielding, conduits (the orange ones you see in many hybrids) and connectors in any automotive electrical system above 60-volts (above which the system becomes officially “high voltage”). Keeping voltage below that threshold means the total cost of these mild hybrid systems can remain between about $800 and $1,200.

That’s important because, as Gustanski told me, the “rule of thumb” for what automakers are willing to pay for fuel-saving technology is about $50 to $100 per percent MPG gain. At 10 to 15 percent increased mileage, these mild hybrid systems are right in that ballpark.

Motor Generator Unit

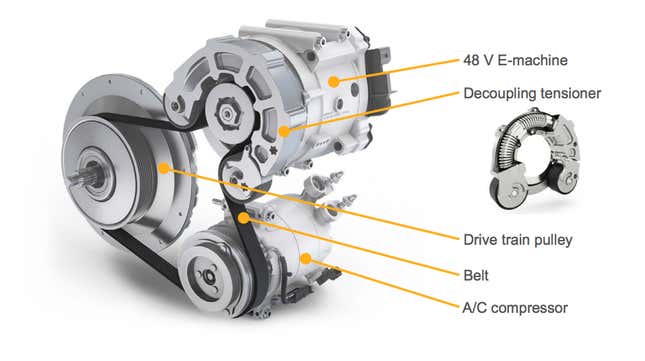

Like an alternator, the motor generator unit is connected to the engine’s crankshaft via an accessory belt, except the 48-volt unit is often liquid cooled and has special tensioners to accommodate the fact that torque will be applied by the MGU and also to the MGU.

In the first case, the approximately 10 kW unit acts as a motor, receiving current from the 48-volt lithium-ion battery in the trunk through an inverter, which changes DC power to AC to drive the motor.

That motor then turns the gasoline or diesel engine over via the drive belt. This then either quickly fires up the combustion engine after a start/stop event (a 12-volt starter remains for cold starts), provides a “boost” of up to around 100 lb-ft of torque to the engine to improve acceleration performance (particularly after a start/stop event), sends calculated torque pulses to the engine to reduce vibration of start/stops, or reduces engine loads at other strategic times to maximize fuel economy.

The unit doesn’t only act like a motor and send torque to the crankshaft—as its name implies it’s also a generator, receiving torque in order to fulfill its most basic duty of generating electricity for the 48-volt battery pack in the back of the car. This happens not only when the engine is on and spinning the belt (like with a conventional alternator), but also when the engine is off and the vehicle is coasting or braking.

This means the internal combustion engine is able shut off the fuel supply, and the wheels actually rotate the internal combustion engine through a locked torque converter. The belt from the motoring engine’s crankshaft then spins the unit, which creates energy for the 48-volt battery.

Thus, the unit acts not just to seamlessly start the car after a start/stop event, perform the alternator’s charging duty, and help reduce the load on the engine by exerting torque on the crankshaft, but it also allows for regenerative braking.

Different Levels Of Mild Hybrids

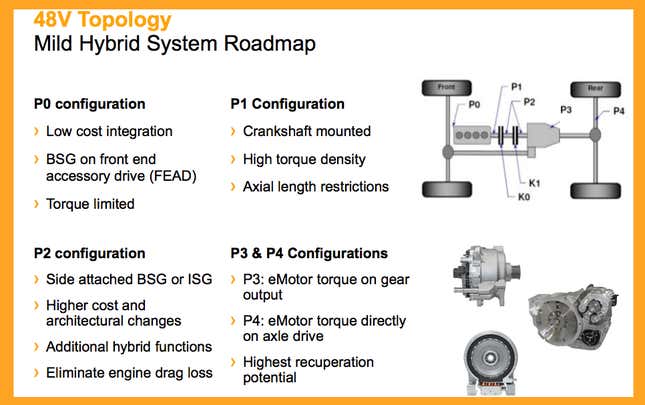

Delphi’s Mary Gustanski told me that, though the company is focusing on MGU-driven mild hybrids that run off the accessory belt (called a “P0" mild hybrid), these low-cost systems are simply a “pathway to EVs,” with the next step likely being “P2.”

P2 mild hybrids, like Mercedes’ inline starter generator system, are significantly more expensive, requiring both major changes to the vehicle packaging environment—as the Motor Generator Unit is now between the engine and transmission—and additional components like clutches. The goal with P2 is to allow the motor to power the wheels without having to turn over the engine, thus reducing drag and improving efficiency.

Continental’s P2 design shown in both pictures above features a drivetrain pulley sandwiched between the engine and transmission, and isolated from both components by two clutches. The MGU is off to the side, and sends torque to the pulley and also the AC via a belt.

To power the car with only electric power without having to drag along the non-running engine, the engine-side clutch opens, and the motor spins the transmission input shaft via the belt and drivetrain pulley.

During a start/stop event on a hot day, both clutches can open, and the unit can send power only to the AC compressor without moving the vehicle or turning over the engine.

Though making space for P2 mild hybrids would be a significant undertaking, and there are more components than in the P0 system that will soon find its ways into many cars around the globe, the ability to drive a car under only electric power, and to run AC with without the engine on could offer major fuel economy and comfort-related benefits.

It’s All For Better Efficiency

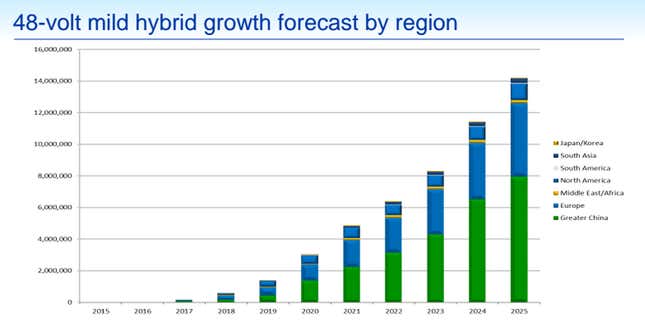

As reps from Continental and Delphi told me, 48-volt drive systems are becoming popular right now for one primary reason: to meet fuel economy and CO2 regulations, particularly those in the EU and China, which require 95 grams of CO2 per kilometer by 2021 and 117 grams of CO2 per kilometer by 2020, respectively. The U.S.’s 54.5 MPG requirement by 2025—equivalent to about 101 gram per kilometer—is also looming.

Running accessories off of 48-volt electricity instead of 12-volts is thriftier not just because of reduced losses (the same reason why we transmit power through power lines at high voltages), but also because, as Gustanski told me, pumps and fans run more efficiently at higher voltages. More importantly, though, is the fact that the 48-volt power supply provides enough electrical power to power devices traditionally spun by the engine’s accessory drive.

Decoupling accessories like water pumps and air conditioning from the engine reduces parasitic drag, and more notably, allows the accessories to set their own duty cycles based on vehicle and customer demands, not simply based on the engine RPM.

For example, maybe it’s the dead of winter and you’re towing a trailer up a hill at 4,000 RPM. On a traditional car, that water pump—driven by the engine— would be spinning very quickly and sending lots of coolant through the engine. But, since it’s cold outside, the engine may not need as much coolant flow to keep the engine happy. So with an electric water pump, you could theoretically save energy by throttling back that pump based on cooling requirements.

Another example, which Gustanski mentioned, is a 48-volt AC system running the compressor at a low speed during highway cruising rather than at very high speeds governed by the engine RPM. The point here, is that allowing components to run at speeds based on required output, and not simply based on engine speeds offers a significant benefits to efficiency.

Gustanksi even mentioned using the 48-volt power supply to more quickly heat up a catalyst in a diesel exhaust system to reduce emissions. Between this, the added luxury electrical features that can now be accommodated, regenerative braking, boost from the electric motor to reduce engine load, more efficient accessories that don’t depend on engine speed, and reduced turbo lag from an electric supercharger, it’s safe to say the benefits of this tech span far beyond that little 10 to 15 percent fuel economy improvement figure.

It’s no wonder industry expert IHS says the market for 48 volt mild hybrids is expected to increase ninefold by 2025, with a total of 14 million vehicles expected to enter production.

That’s great news for suppliers like Delphi and Continental, but it could also be also good news for consumers, who are promised better fuel economy, more provisions for high-tech electronic options, and increased performance —all at relatively minor costs to MSRP, rear storage space and overall weight.