Porsche’s first fully electric car is here, and depending on whom you ask, it could be the most serious competition the Tesla Model S has faced yet. It’s called the Porsche Taycan, and it is an all-electric sport sedan promising up to 750 horsepower, acceleration from zero to 60 mph in 2.6 seconds, and a fast-charging 800 volt battery with 280 miles of range based on the European WLTP cycle.

I spoke in detail with Porsche’s engineers about this electric powerhouse, and I learned it’s a wild piece of technology unlike any Porsche that’s come before it. Here’s everything you wanted to know, and probably some stuff you didn’t know you wanted to know.

(Full Disclosure: Porsche flew me to Atlanta, put me up in a nice hotel, fed me food, and let me talk to some nerdy engineers about the new Taycan).

The Stuttgart-based company invited me to the Porsche Experience Center in Atlanta, where the Taycan’s head engineers assembled to discuss the impressive specs of the two Taycan trims set to launch later this year, the Taycan Turbo and Taycan Turbo S.

Both cars can make up to 616 horsepower for 10 continuous seconds, and both offer “overboost” functions, with the Turbo capable of a 2.5-second continuous output of 670 horsepower and 626 lb-ft of torque and the Turbo S making a whopping 750 horsepower and 774 lb-ft for that short duration.

This allows the the Turbo and Turbo S to achieve zero to 60 mph times of 3.0 seconds and 2.6 seconds, and quarter mile times of 11.1 and 10.8 seconds, respectively.

Key to these figures, Porsche stressed during the presentation, is that the performance is repeatable, with both cars allegedly managing the aforementioned acceleration performance even after 10 runs without any significant “derating,” or performance loss. To drive that point home, Porsche pointed us to the video above of a Taycan ripping from zero to 124 mph (the vehicle’s top speed is 160 mph, if you were curious). Porsche says the car did this in under 10 seconds 26 times in a row, with “less than one second difference between first and last acceleration.”

The company also pointed out that the first-ever all electric Porsche completed a 24 hour endurance run at the Nardò high-speed track in Italy, and despite the up-to-108 degree F air temperatures and the fact that the car had to be recharged during the over 2,100-mile run, the Taycan achieved an average speed of 89 mph.

Porsche wants these examples, and the Nürburgring time—which is apparently the quickest of an EV sedan—to highlight that the Porsche Taycan is not just about being quick, it’s about being consistently quick.

This could help the car stand out over the Tesla Model S, which seems to outperform the Taycan on paper; I look forward to seeing independent track tests to find that out. (The Model S, it turns out, may be headed to the ‘Ring too, so we’ll see how that goes.)

To break down how the Taycan manages its performance figures, which also include a fast claimed charging time, Porsche broke the technical workshop into five sections: powertrain, chassis, body, charging, and interior.

Let’s start with the fun one.

Porsche Taycan Powertrain

The Motors

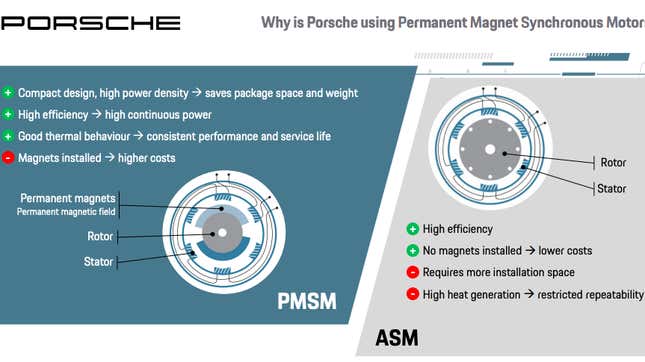

The Porsche Taycan is powered by two permanent magnetic synchronous electric motors, or PMSMs. Unlike AC induction motors used in some other electric vehicles like the Tesla Model S (though it and the Model 3 also use a permanent magnet motor), PMSMs utilize rare-earth magnets embedded into a rotor (which is what the output shaft is connected to) to create a permanent magnetic field. This spins in sync with a stator’s (as shown in our look at a torn-down Model 3, a stator is just the “pipe”-shaped stationary bit of the electric motor consisting of a bunch of copper windings) rotating magnetic field, which is created by the sinusoidal AC input from the inverter, a device that turns DC power from the battery to AC power for the motor.

By contrast, an AC induction motors’ rotor doesn’t include rare-earth magnets, and instead consists of windings. As the inverter sends AC current to the stator and creates a rotating magnetic field, that magnetic field induces a current in the rotor windings, which creates a magnetic field. That rotor’s magnetic field interacts with that of the stator, and the rotor spins, yielding mechanical torque. It’s called “asynchronous” because the rotor lags behind the rotating magnetic field in the stator—a phenomenon called “slip.”

The advantages of the permanent magnet design, Porsche mentions in the slide below, include high efficiency—particularly at the low and middle speed range—smaller size, and better cooling capability, though at a slightly elevated price point.

Even Elon Musk has talked about AC induction motors’ cooling limitations, which Porsche powertrain manager Dr. Boyke Richter says are a result of the rotor requiring current, which creates heat that’s difficult to remove.

“This limits the repeatability of the electric machine,” he said. He also went on to mention how important size was, saying: “With the same power and torque level, the asynchronous machine is always a little bit bigger.”

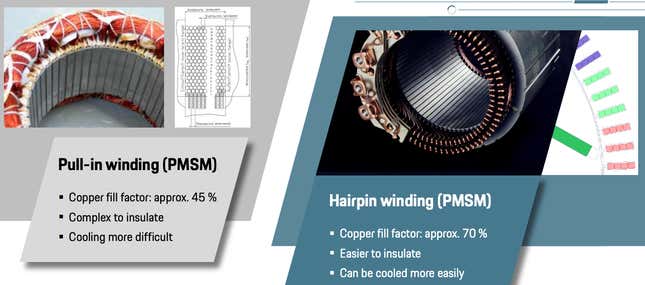

Porsche also mentioned the rectangular hairpin-style windings making up the stators—a setup we’ve seen before on the Chevy Bolt—as an advantage in that it can apparently fill the slots of the stator with fewer gaps than a traditional pull-in winding design.

The concept of fitting more copper in a given amount of space is quantified by a metric called a “copper fill factor,” which Porsche says can be around 70 for a hairpin setup instead of 45 for the traditional “pull-in winding” stator setup.

“By increasing the copper fill factor, you increase the performance,” Richter told us. Not to mention the setup apparently allows for better cooling of the windings, with Richter saying it offers “better direct contact between the copper and the stator pack, meaning you get the heat that is generated inside the copper by the current flowing through it better out of the machine, and again... better cooling possibility and more repeatable performance.”

The Transmissions

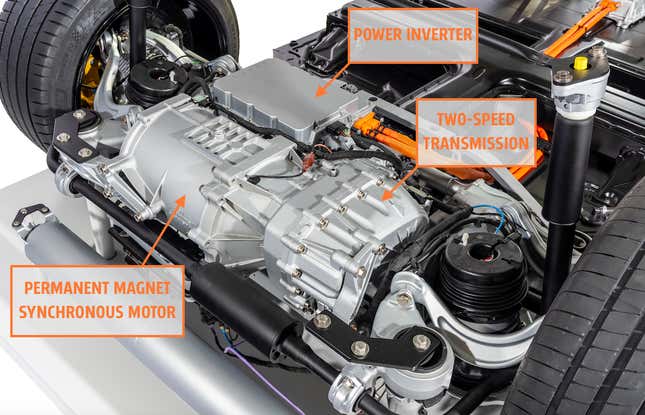

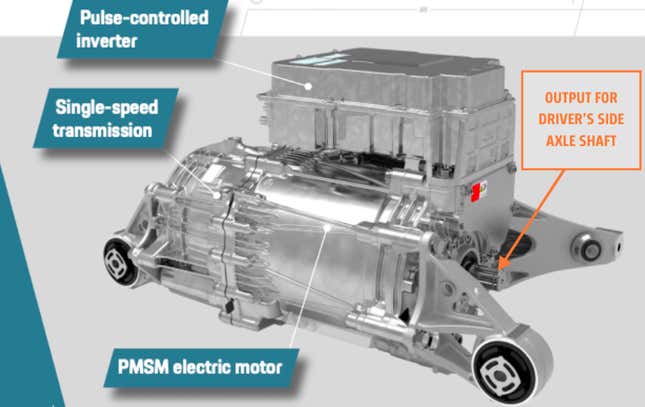

Of the two motors in the all-wheel drive Porsche Taycan, the one in the rear is more powerful. It makes 449 horsepower and 406 lb-ft of torque (or 450 lb-ft during launch with the Turbo S), and sits parallel to and aft of the axle centerline, sending power forward through a Porsche-designed and manufactured two-speed gearbox. That gearbox has a first gear ratio of roughly 16:1 and a second gear ratio of 8.05:1.

The “rear axle module,” as Porsche calls it, consists of the motor, transmission, and power inverter, the latter of which, as previously mentioned, takes DC current from the battery and converts it to AC current for the motor. That entire module, whose casing appears to be made largely of cast aluminum (Update: Porsche says: “We will not divulge the exact materials, but cast aluminum is present in the powertrain.”), weighs about 375 pounds, Porsche claims.

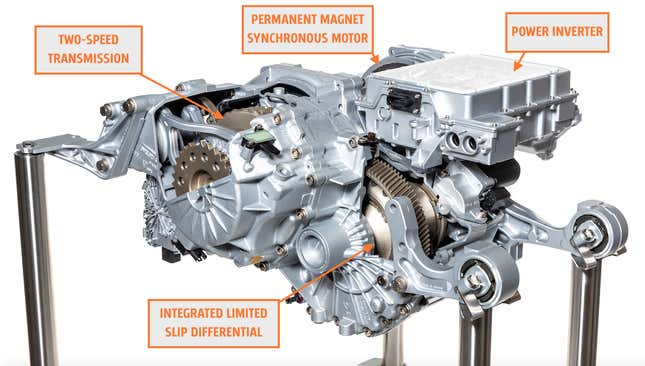

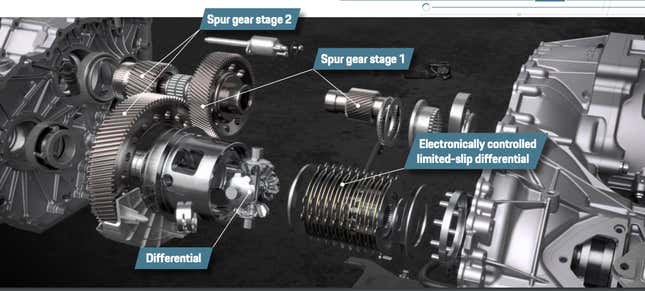

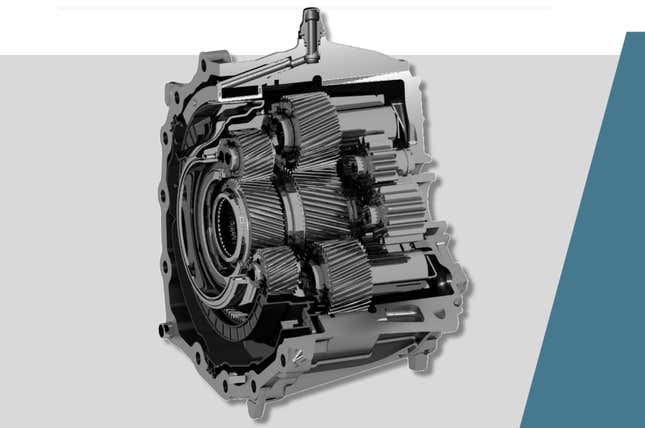

The transmission, which also houses a clutch-based electronic limited slip differential (I guess you could call this gearbox a transaxle, then), is a fascinating unit, as I know of no other mainstream electric vehicle in the U.S. that currently offers a two-speed gearbox.

Porsche says it does in order to improve efficiency, and also to help optimize both low-speed acceleration and top-end speed—pretty much exactly the benefits that auto supplier ZF claims of its new two-speed EV transmission.

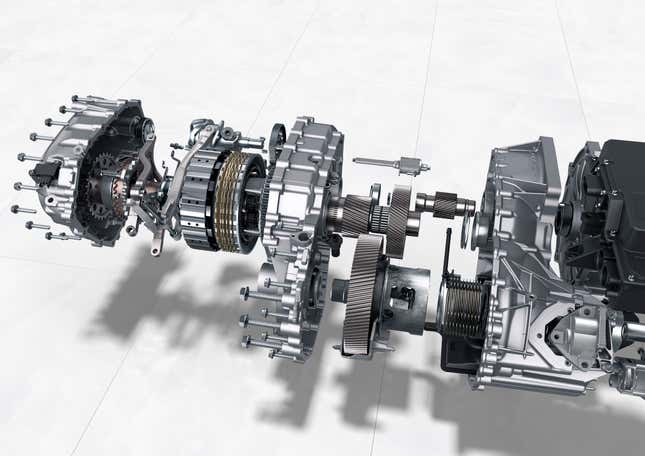

Here’s another angle of the rear axle module:

The transmission has a torque capacity of 406 lb-ft, which is oddly less than the max output of the rear motor during launch (I’m trying to clarify this with Porsche). It and the entire rear module was designed to be as compact as possible and to sit flat to allow for ample trunk space. It is set up such that the motor is at the rear, and its output shaft enters a transmission, which stretches forward to a differential whose output is in line with the rear axle. Mounted just in front of the motor and above and towards the passenger’s side of the diff is the 600 amp power inverter box.

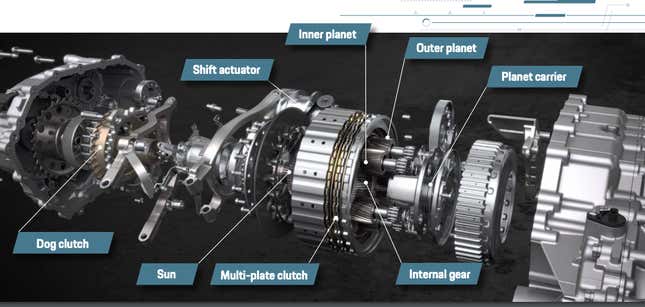

Here’s a look inside the transaxle case:

“We integrated only one actuator in this transmission for all different stages—first gear, second gear, neutral, reverse, and park,” Dr. Boyke Richter told journalists.

Referring to the main shaft of the two-speed trans, Boyke explained the innards. “On the upper part, you see the actuator, it actuates two levers that are connected with a dog clutch and a multiplate clutch. Inside the multiplate clutch there’s a planetary gearset that ensures the ratio for the first gear,” he told us.

In first gear, he explained, the multiplate clutch is open and the dog clutch is closed, with the planetary gearset yielding the 16-ish-to-one ratio. “When shifting to second gear, the dog clutch opens, and the multiplate clutch is closing, blocking the planetary gearset, and by this blocking, we spare the losses of this gearset, and we’re able to increase the efficiency...[in] second gear,” he continued.

“On the output shaft, we have the differential itself,” an electronically controlled limited slip diff, which is “the same component as you already know from [Porsche’s] other vehicles,” he went on.

We’ve seen other manufacturers like BMW (in a development car, admittedly) use two electric motors in the rear, avoiding a differential entirely to achieve more instant torque vectoring capability, but—for packaging reasons, and likely cost, I’d suspect—Porsche decided for a single motor and a conventional limited slip differential.

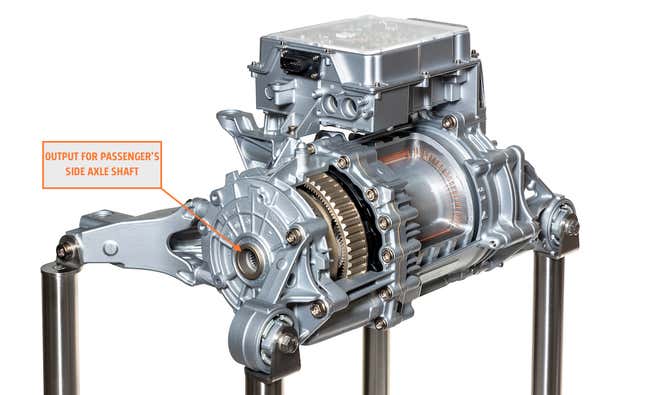

The single-speed front drive module is similarly fascinating in that, like on the Jaguar I-Pace, it incorporates a coaxial transmission design. The transmission bolts directly to the end of the motor, which is located right on the axle centerline, between the front wheels. In fact, one of the front CV axle shafts actually passes through the center of the motor’s rotor to hook into the transmission.

The image above shows the passenger’s side output location, and the picture below shows the driver’s side output shaft:

Also shown is the inverter, which, for the front motor, comes in two flavors: 300 amp peak output (190 amp continuous) and 600 amp (380 amp continuous), with the latter coming in the Turbo S and enabling a maximum output of 255 horsepower and 325 lb-ft of torque during short launch events (and 295 lb-ft for longer durations). The standard Turbo model’s front motor, with its 300 amp inverter, pumps out 238 horsepower and a maximum of 221 lb-ft.

The two inverters, which yield 168 pound and 157 pound total weights for the front axle module, save cost by sharing quite a few components, Porsche says. It’s not clear if the 600 amp rear inverter is the same as the 600 amp optional front inverter, but I bet it is. (Update: Porsche says it’s different).

The weight of the coaxial transmission, which features two planetary gear sets and offers an 8.05 reduction (the same as second gear on the rear motor), is much lower than that, at just 35 pounds dry. It has a 332 lb-ft torque capacity when accelerating and a 221 lb-ft torque capacity when sending torque the other direction when recuperating. This regenerative braking, Porsche says, happens mostly up front, but also at the rear motor, with maximum power recuperation at 265 kW as measured at the battery and maximum longitudinal deceleration of 0.39 G.

Porsche says the transmission is passively cooled, using the water jacket around the electric motor.

Shifting That Two-Speed Transmission

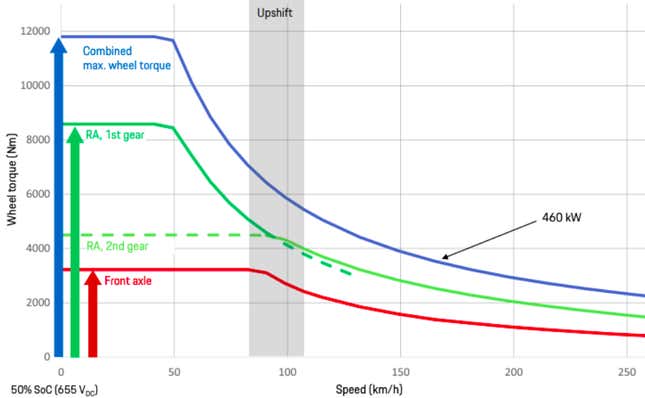

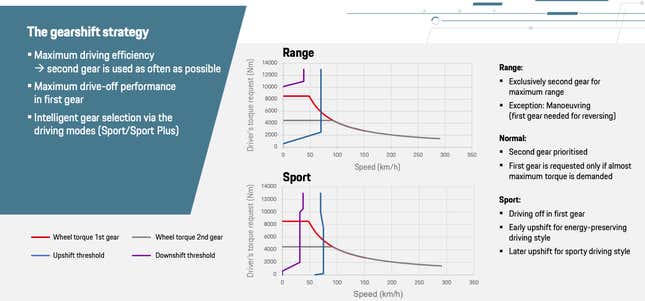

What’s most interesting about all of this is how Porsche sets up the shifts in the rear two-speed transmission. To demonstrate the advantage of the two speed, Porsche showed curves of wheel torque (which is directly related to vehicle acceleration) versus vehicle speed for each motor/gear ratio combination—see below. (These look like typical EV torque curves).

As shown, at about 100 km/h, or 62 mph, first gear runs out of steam, and the motor isn’t able to send much torque to the rear wheels (and at 81 mph, the motor hits its 16,000 RPM max speed), which hurts vehicle acceleration.

It’s at the point around 62 mph vehicle speed that the Taycan upshifts, yielding the solid green curve you see below, allowing for more torque at the wheels, and thus more acceleration to a higher top speed.

The shift strategy changes based on the drive mode, which hold gears differently. Range and Normal mode, Porsche told us, prioritize second gear to optimize efficiency. It is worth noting that, in some cases, the Taycan can actually run completely in front-wheel drive and decouple the rear transmission to reduce losses.

Though Porsche considered it, the front transmission has no clutch to allow for decoupling, so the motor is always mechanically connected to the wheels. This, if I understood it correctly, was done for packaging and reasons related to vehicle control, and with the understanding that the small motor and planetary gearbox don’t yield too high losses.

Back to the modes: Porsche says “Range” only goes into first for reversing functions (this is due to mechanical constraints, as I understand it) and “Normal” downshifts during heavy pedal inputs. “Sport” mode, on the other hand, holds first gear as long as possible to maximize acceleration. Porsche even provided some shift maps below:

The map here doesn’t look that different from that of a traditional transmission, with the blue and purple lines representing when the vehicle would upshift or downshift, respectively. If I’m reading this right, looking at the “Range” plot, you can see that at only low vehicle speeds and extremely high torque requests (in other words, the driver is deep on the throttle while traveling slowly), you’ll cross the purple line and downshift to first.

Then, even if you keep your pedal buried, the car will shift to second around 75 km/h. Otherwise, in “range” mode, you’ll be in second always. (In the slide above, Porsche says “Range” stays exclusively in second gear, so perhaps I’m misreading the shift map. (Update: Porsche confirmed that even “Range” mode will downshift to first).

The “Sport” map shows that even at low vehicle speeds and low torque requests (your foot is barely on the pedal), you’re in first gear, and you won’t upshift until you hit roughly 75 km/h. This shifting, in case you’re wondering, happens roughly as quickly as a dual-clutch transmission shift.

“We are not faster [than a dual clutch],” Richter said, “because we have a large ratio spread between first and second gear,” and therefore transmission needs time to synchronize. Still, the good news is that, according to him, there’s “no traction interruption during shifting.”

Battery and Charging

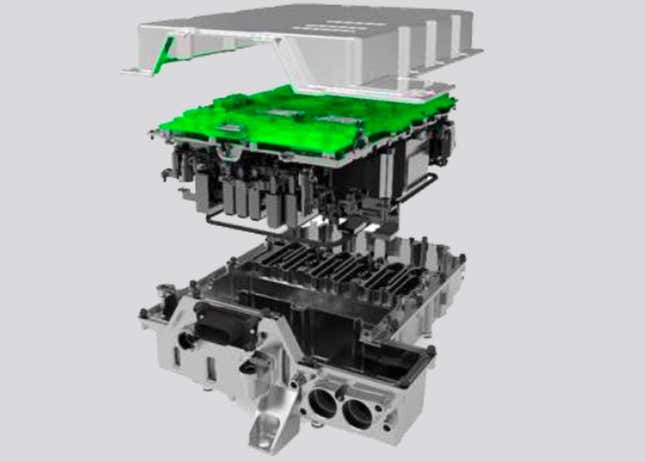

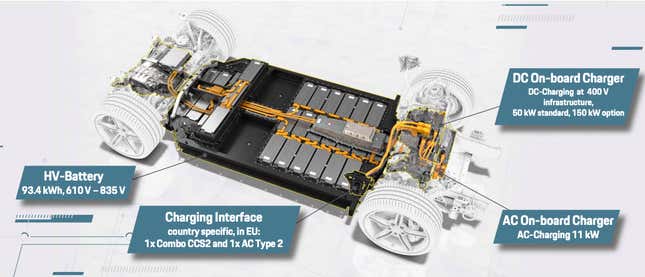

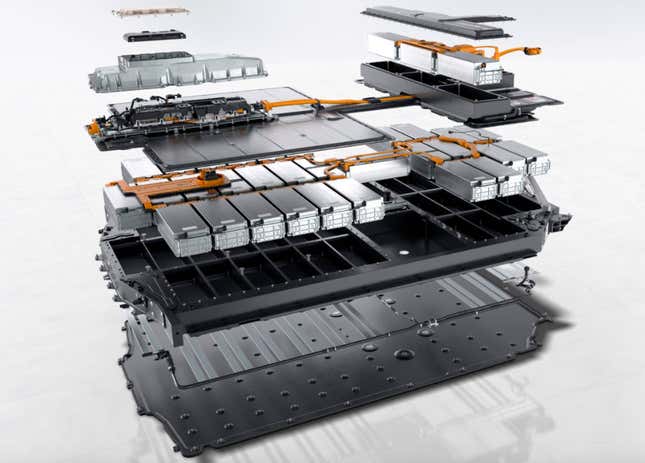

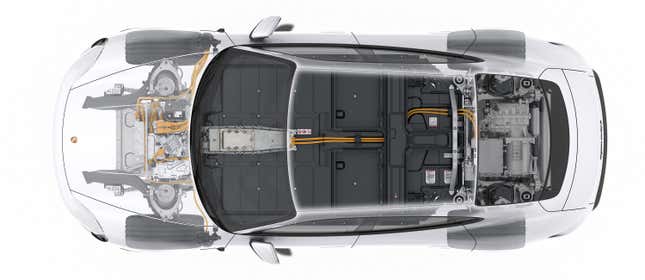

The Taycan’s battery pack consists of 33 cell modules, each of which contains 12 individual 64.6 amp-hour LG pouch cells. They are arranged such that half of the cells, 198, are in parallel with the other half. The big number that’s been thrown around for years now is “800,” as it’s a rather high system voltage for an EV.

In the case of the Taycan, the actual voltage sits somewhere between 610 (depleted) and 835 volts (when full), with a nominal voltage of 723 volts. Maximum energy content is 93.4 kWh, which is a bit less than the Tesla Model S at 100 kWh.

You can see the full battery pack above; notice there’s a protrusion where a center transmission tunnel might be on a typical car—that’s the battery management system. You can also see two rectangular voids aft of that; those are the “foot garages” for the rear passengers. And while that leg space for rear passengers required Porsche to remove battery modules, the company compensated by placing modules cross-car under the rear bench.

Porsche says it went with an 800 volt architecture to meet efficiency, vehicle performance, and battery charging time targets. The latter was key, since the company didn’t want to have to make the battery pack too large and heavy (the Taycan, at over 5,100 pounds, still outweighs the Model S).

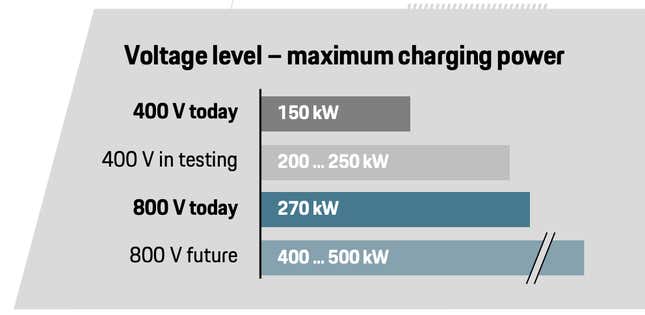

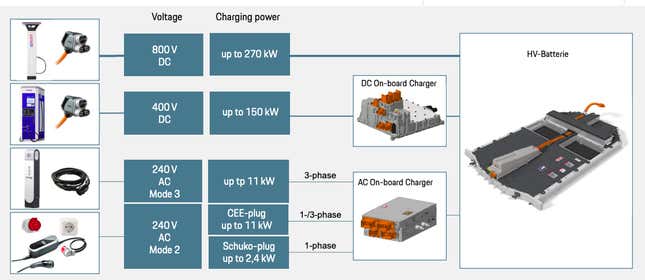

Speaking of charging, Porsche’s head of electronics Joachim Kramer stated: “With double voltage [of a conventional electric vehicle]... you simply could double power [with] existing current.”

But the Taycan’s 800 volt system does not offer twice the charging power of a 400 volt EV, it offers less than that at, 270 kW of maximum continuous charging power, because the battery introduces limitations. “You could theoretically go higher, but then you would sacrifice battery life—what... nobody wants to do,” Kramer said.

Still, the architecture is allegedly built to be future-proof. “Once the battery gets better... and the next generation is coming...the architecture of this 800 volt high voltage system is actually capable to go up to charging powers with the existing connector system—this combined charging system what’s on the market so far—to 400, even more, kilowatts peak charging power.”

In addition to charging times, Porsche says the 800 volt system theoretically yields more efficient power transfer and allows for thinner wiring, since for a given power output, a higher voltage system sends less current, and it’s current that generates lots of heat in wiring (losses go up with current squared). “It’s simply more efficiency in the complete high voltage system,” said Porsche’s electronics guru.

More efficient power transfer and less wiring, Porsche states, means less weight and higher continuous power transfer without derate, but the 800 volt system does have drawbacks.

“We had to develop the power electronics, the battery electronics, the charging electronics completely new—it wasn’t there on the market,” Kramer told us, going on to say that, while this cost the company time and money, it shouldn’t be more expensive long term, since the components are largely similar to lower voltage systems.

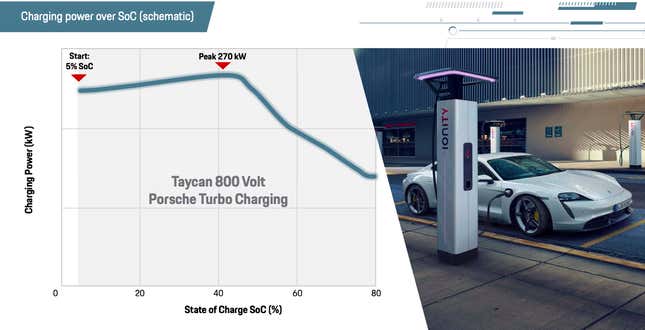

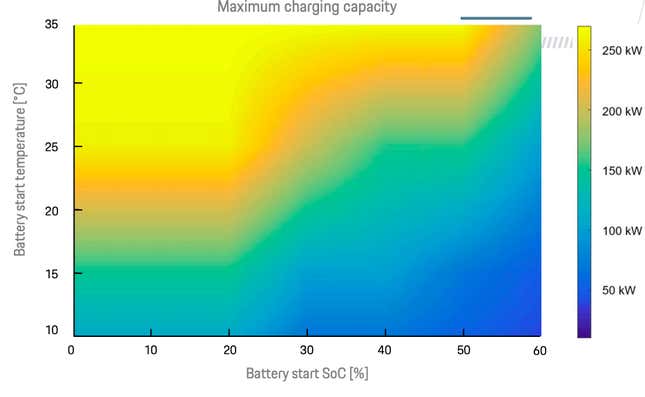

Practically speaking, Porsche advertises a minimum charging from 5 percent state of charge to 80 percent in 22.5 minutes. The plot above shows that, because the battery can only take a peak current of 334 amps, at a low voltage, the peak charging power (power is volts times amps) is less than the 270 kW maximum, which occurs at about the higher voltage corresponding with a 40 percent state of charge.

As voltage increases above about 40 to 45 percent, the aforementioned battery limitations come into play. “By then you then need to reduce the power to actually protect the battery... so no over-voltages occur in the battery,” Porsche told journalists.

Of course, it’s not just battery state of charge that affects charging capacity, it’s also temperature, as the plot above shows that batteries generally like to be between 25 and 35 degrees C, and that as the state of charge increases, charging power drops.

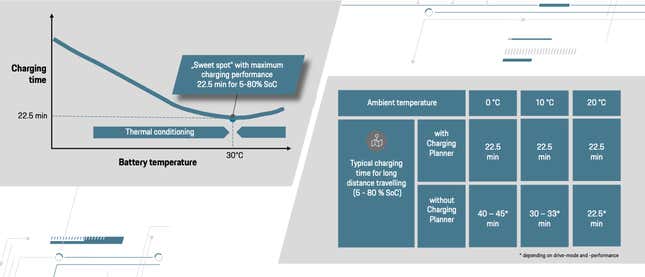

Per the slide above, Porsche identifies approximately 30 degrees C as the “sweet spot” of battery temperature to yield 270 kW of charging power and the minimum 5 to 80 percent battery charging in 22.5 minutes. Below that, a “thermal preconditioning system” kicks in, and if the car knows that a driver wants to charge soon (if, for example, a performance charger has been input into the GPS), a “Charging Planner” will get the batteries to the right temperature so that they can charge at the maximum rate even at 0 and 10 degrees ambient temperature.

Porsche mentions that less preconditioning is needed if a driver builds up heat in the cells by driving hard, or if the car is being charged in a lower-performance charging station (for example, 50 kW maximum charging doesn’t require any preconditioning).

As for charging ports on the car, there are two, with the U.S. model getting one on the driver’s side to accommodate a type one AC plug, and a CCS type 1 style plug—which accommodates AC and DC Charging—on the passenger’s side.

Porsche even offers an optional ice-breaking function for the charge port doors that vibrates the doors back and forth a bit and cranks up the door motor’s torque. Those doors are opened via hand gestures or a button on the center console.

Any Taycan, when hooked to a high-performance charger capable of 800 volts, can offer up to 270kW of charging directly to the battery. That will get the vehicle from 5 percent to 80 percent state of charge as quickly as 22.5 minutes and add 62 miles to a dead battery in under six minutes.

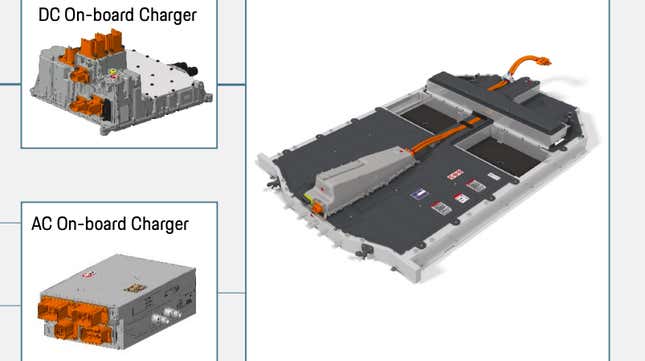

But, when using a typical 400 volt DC charger, the Taycan’s standard 50 kW unit DC onboard charger (which boosts the 400 volts to 800 to charge the battery) can get the vehicle’s battery from 5 percent to 80 percent in 93 minutes and add 62 miles of range to a depleted battery in about half an hour. An optional 150 kW onboard charger increases charging speeds to be in line with those of other 400 volt EVs, Porsche says. (Update: To be specific, with the 150 kW optional charger, Porsche says to go from 5 to 80% state of charge takes 36 minutes).

To accommodate at-home charging or 240-volt “level 2" charging stations, there’s also an AC onboard charger that converts AC to DC current for a charging power to the battery up to 9.6 kW. This yields a charging time from zero to 100 percent in a minimum of 10.5 hours. (Note that the image above states 11 kW; I assume this is a difference in U.S./E.U. charging).

The image above shows the charging port setups on Taycans offered in various markets.

Body And Battery Structure

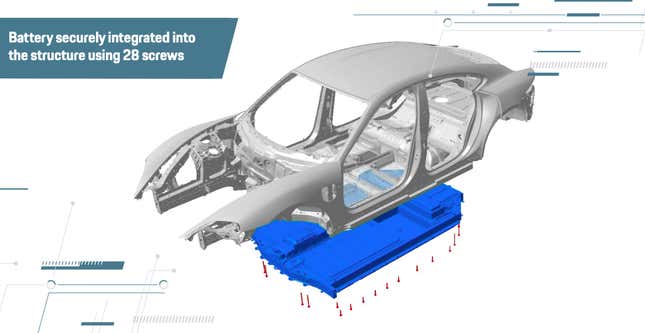

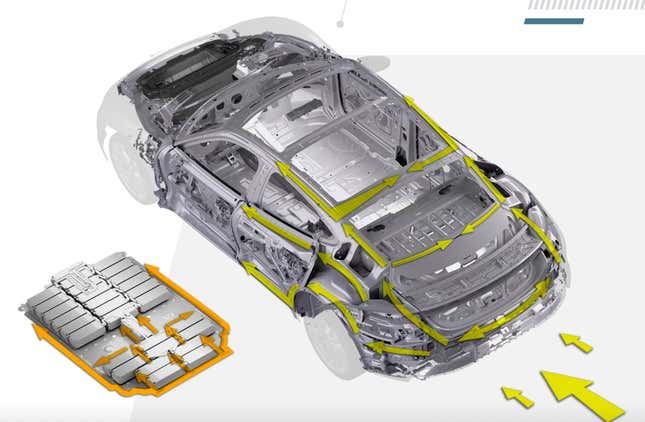

When discussing a from-the-ground-up EV, the body and battery pack are important elements of the overall structure, so Porsche engineers told me that the pack—which is bolted to the body structure via 28 bolts—represents about 10 percent of the vehicle’s overall stiffness. The company claims that the Taycan’s chassis is the stiffest of any Porsche available.

Speaking of the battery pack, dropping its 1,389 pound heft requires not just undoing the 28 screws and disconnecting the high voltage connector, but also removing about 10 screws holding parts of the front and rear subframes. With the screws out, the subframes have to move a bit, and then the battery can drop.

“It’s really quite easy,” claims Steffen König, who led the Taycan’s body design. To access the modules, the top cover, which is glued and bolted in place, is removed.

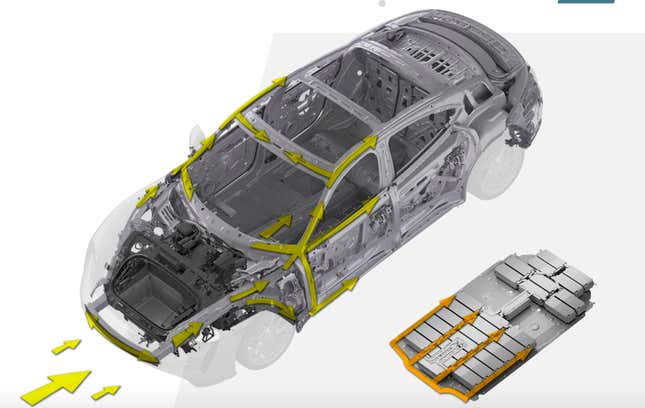

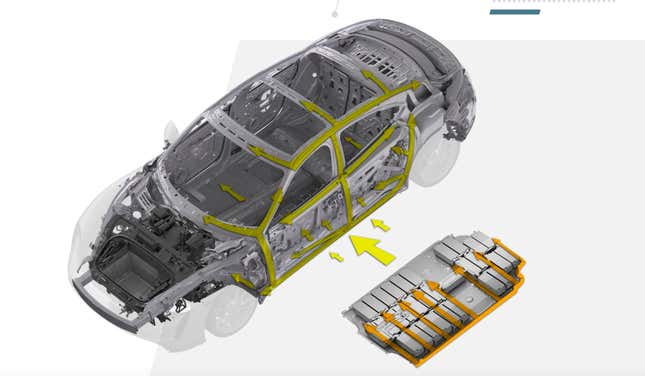

The battery tray itself weighs 331 pounds, and is an important structural element for front, side, and rear crashes as shown in the images below, which show load paths for the aforementioned crash scenarios.

“Without the battery, the car isn’t crash-safe,” König told us.

Porsche describes the construction of the battery tray, saying:

The waterproof housing is a sandwich construction consisting of a cover at the top and a bulkhead plate at the bottom. The truss-design battery frame with multiple subdivisions is mounted in between. The cooling elements are glued on underneath the bulkhead plate. The battery housing is secured by means of a steel protective plate. For the battery frame, the developers opted for a lightweight aluminium design.

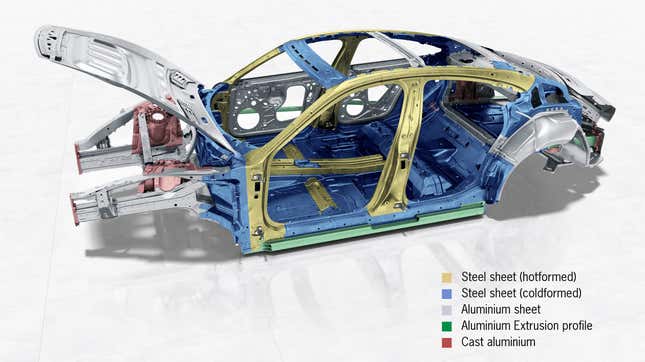

One of the most obvious crash mitigation components are the 0.6-inch extruded aluminum honeycomb structures running the length of the rocker panels (shown in blue below), which help protect the battery and occupant in side crashes:

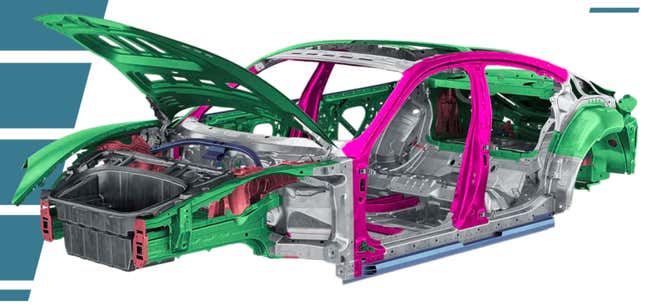

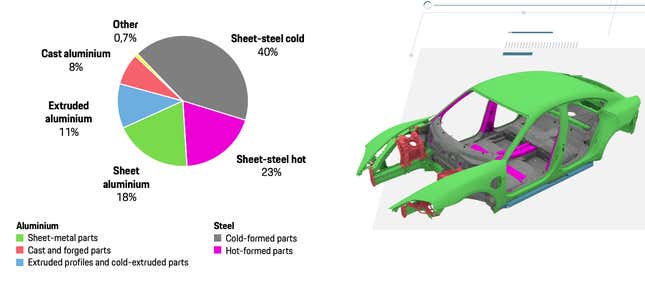

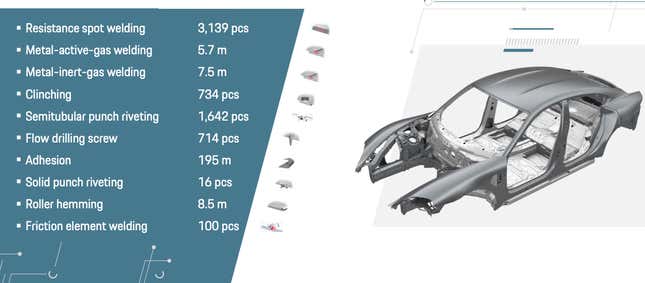

Speaking of body components, the Taycan body’s material makeup is largely conventional for a Porsche. Nothing particularly exotic, just a bunch of steel and aluminum not too different from what we saw in the Porsche Cayenne. Porsche itself refers to the body as “quite a normal body for us; it’s a mix of a lot of materials.”

But, as “normal” as it may be, I won’t deny you an opportunity to see some beautiful CAD images, like the one above, which show steel used in the pillars, floor, and firewall, and aluminum used in the doors, wheel arches, front longitudinal members and strut towers, and sheetmetal.

Porsche claims it used steel in the floors and main body structure, and not as much aluminum as in the Panamera, for acoustic (presumably road noise) reasons. “The frame of the body is normally in aluminum. In our case, it’s sheet steel-cold because of the acoustic of the car; we have... no engine in the car, so we have to be really easy to drive, so we have to do this for this acoustic [improvement].”

I’m not a body engineer, so it’s going to be hard to convince me that price wasn’t a major factor too, but hey, that’s just what Porsche’s claiming here.

And if you are a body engineer wondering how the company went about combining all of those disparate metals into one structure, the answer is: Lots of welding, riveting, hemming, clinching, and screws.

Aerodynamics and Cooling

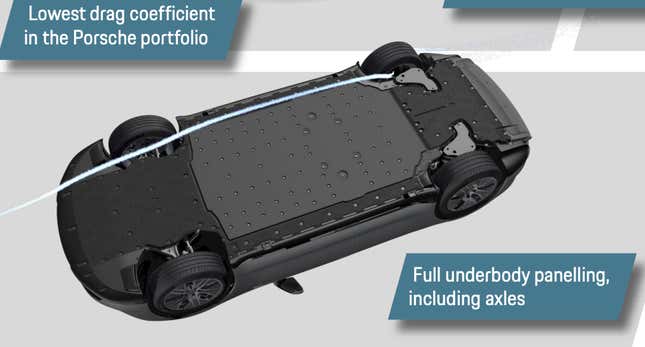

The Taycan has the lowest drag coefficient, or Cd, of any Porsche at 0.22 in the case of the Turbo (The Turbo S’s is 0.25). The front surface area, which—like the drag coefficient, air density, and vehicle velocity contributes to overall drag—is 25.1 square feet, and while I can’t find the exact corresponding figure for the Tesla Model S, I did find a 2014 Car and Driver article that listed a 25.2 square-foot frontal area and a 0.24 Cd for the Tesla. (The newer Model S has a 0.23 Cd, and while I bet the frontal area is close to the same, I’m not entirely sure).

As I understood it from Porsche, in the front of the Taycan are two openings. One for each of the two heat exchangers, which include a condenser (which is just a heat exchanger like a radiator, except with refrigerant running through it) on the passenger’s side and a radiator on the driver’s side. Each of those openings, I think, also feed the duct on that side to cool the 16.5-inch (ish) 10-piston front brake rotor.

In the center of the car, what appears to be a grille opening is there to house the radar and camera. The tall openings below the headlights are there to create an “air curtain” around the wheel openings to guide air around and not into the wheel housings, which are filled with either 245 or 265-section tires (the rears are either 285s or 305s).

Other aerodynamic treatments include a completely flat underfloor, which includes includes a flat pan under even suspension components (like the rear control arms), a wide rear diffuser, and an active spoiler with three positions.

The three positions are fully down (used when the vehicle is parked, for “design reasons,” Porsche told us), Eco, where the spoiler is up a bit, and Performance, where the wing is fully up to reduce rear lift. Those modes also dictate the status of the “air flaps” in front of the heat exchangers, which—as I understood it—function just like active grille shutters on conventional ICE cars.

As I heard it, the rectangular brake ducts (shown above) share the flaps with the heat exchangers, which are closed in Eco mode in order to send air around the car to improve aerodynamics. On top of the wing and front air-flap positions, the Taycan’s air suspension also offers aero benefits, lowering the car when cruising on the highway.

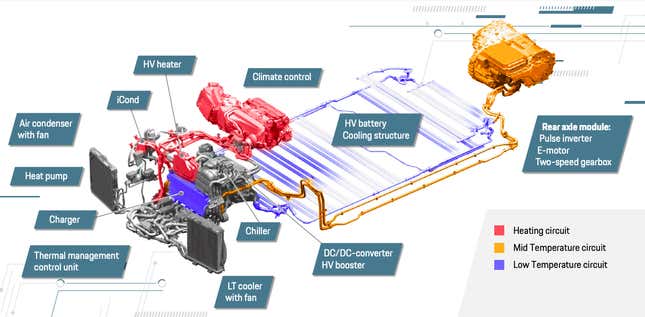

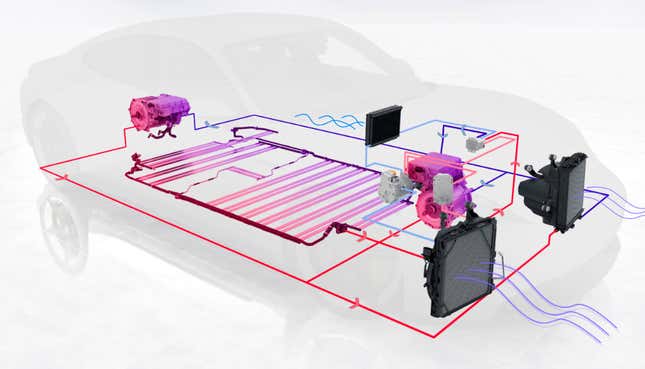

But you can’t talk about aerodynamics and not discuss cooling, as they’re intrinsically linked. Unfortunately, Porsche didn’t dive too deep into how the Taycan’s cooling system works, especially not how valves connect the heating, mid, and low-temp circuits.

All I know is that there’s a condenser and radiator up front, a heating element to help warm the battery and cabin, a chiller using the A/C system to pull heat from coolant before it runs under the false floor of the battery pack, and that Porsche has cooling methods in place for the on-board chargers, DC/DC converter (which is under the hood, and converts high voltage to 12-volts to power cabin accessories), inverters, motors, and transmissions.

Porsche describes the hardware a bit in its press release, writing:

On the hardware side, the thermal management system consists of a networked line system with a coolant radiator (front, left-hand direction of travel), three coolant pumps, six coolant valves, two fans and ten coolant temperature sensors. This is supplemented by the linked components from the air-conditioning system with a climate condenser (front, right-hand direction of travel), a separate evaporator (chiller) and a heat exchanger for air-conditioning/cooling (iCond).

You can see some of the components below, including the heat exchanger located under the false floor beneath the battery modules in the battery pack. It looks like a bunch of long, flat “tubes” arranged in pairs running from one long longitudinal “tank” to one on the other side of the pack :

It’s hard to tell how it all works based on just this one circuit diagram, but it looks like the front and rear axle modules—including their inverters, motors, and transmissions—are cooled by liquid coolant coming straight off the radiator at the front driver’s side of the car. Once that cold coolant (which is dark blue in the image above) goes through and picks up heat from each of the drive modules, it then becomes red in the diagram, and goes back to the radiator to lose heat before cycling back to the motors/power electronics.

As for the batteries, based on the image above, it appears that cold refrigerant (light blue) comes out of the condenser at the front passenger’s side of the vehicle, enters a compressor, goes through the evaporator that allows for cabin air conditioning, and then into a chiller. There in the chiller (just a refrigerant-to-coolant heat exchanger), the refrigerant picks up heat from liquid coolant that has gone through the battery pack, yielding colder coolant and warmer refrigerant. The colder coolant (dark blue) exits the chiller to go back into the pack to cool batteries, while the warm refrigerant eventually makes its way back into the condenser to dump heat to oncoming air.

Again, these are just guesses based on the diagram above, and I’d definitely like to learn more—especially since the image above doesn’t show all the pumps and valves in the system.

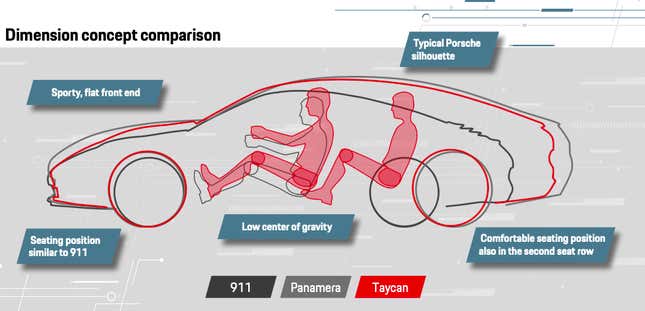

Chassis—How Does It Compare To The Panamera?

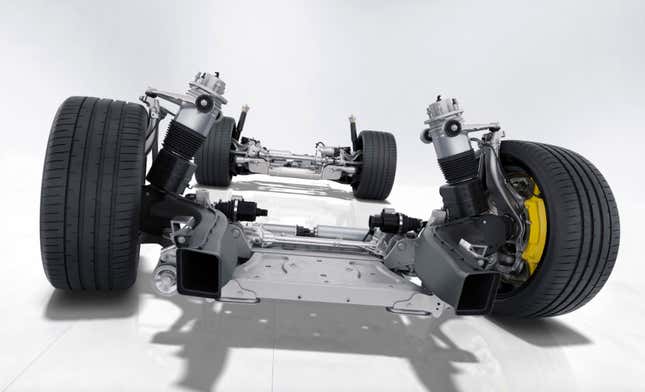

If you’re among those wondering if Porsche used components from its other four-door sedan, the Panamera, in the Taycan’s design, the answer is “yes.” At least in some ways.

First, let’s look at the sizes. The image above shows the silhouette of the Taycan in comparison to that of the 911 and Panamera. The EV’s nose is lower than that of the Panamera, and overall, it’s a bit shorter in length and height, though the seating position is a bit higher. Still, Porsche says the Taycan’s center of gravity is lower than that of a 911 GT3, which I guess isn’t surprising considering how much the battery pack weighs on this thing.

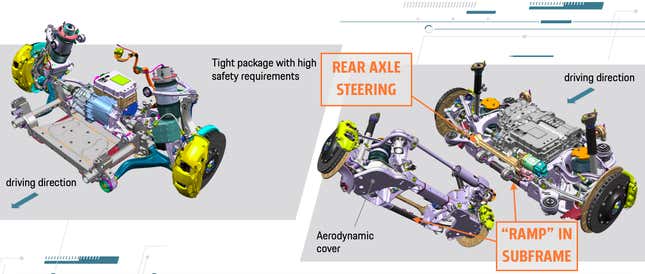

Dr. Ingo Albers from Porsche’s chassis team said right away that the Taycan’s suspension is indeed “derived from the Panamera,” and that the team wanted to use quite a few of the Panamera’s suspension components, as “it would be very efficient to use them.” But, while the new Taycan shares control arms, bushings, bearings, and the wheel carrier with its internal combustion engine-powered sibling, Albers said “[Porsche engineers] couldn’t’ use the complete subframe.”

Looking at the overlapping silhouettes and the image of the front and rear subframes above makes it pretty obvious why that’s the case. Though the rear axle module isn’t huge, the motor, inverter, and two-speed transmission dwarf the Panamera’s differential.

And while this was a main reason why Porsche had to design a new subframe, Albers also talked about safety. “We were not allowed to have any intrusion into the cell modules,” he mentioned, before pointing out a ramp-like member in the subframe to push drive module components up and over the battery pack during a rear collision.

He also mentioned the importance of the rear axle steering to safety. “The rear axle steering is a kind of barrier for the... components if it comes to a rear crash,” he told us, saying that if the vehicle doesn’t come with rear axle steering, there’s a member there to act as protection.

As for the front suspension, not only did the team have to ensure that the subframe kept the battery safe during a collision, but even if that weren’t critical, using the Panamera’s suspension wouldn’t have been possible due to the low height of the five-seater electric sedan’s hood, which is enabled by a lack of a large internal combustion engine in that space.

“The components of the Panamera, they would just stick out. They were too long,” Albers told us. As a result, he said, “[engineers] brought down the upper control arm, and the complete air suspension.”

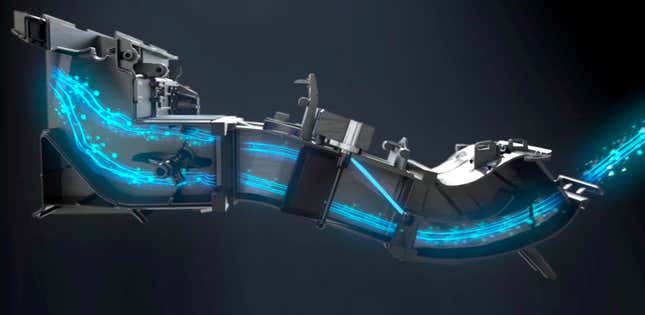

There’s Lots More Cool Tech

As you might imagine with a ground-up electric sport sedan, there’s a lot more to be said, but I’ve already written over 5,000 words. So, to avoid my editor yelling at me, I’ll have to conclude without describing how the fun HVAC air vent system’s (shown above) aim is adjusted via touchscreen.

I won’t relay Porsche’s discussion on charging infrastructure, I won’t show the center console screen that lights up and tells you the battery state of charge when it’s detected the fob is nearby, I won’t talk about the passenger’s side infotainment screen that senses when there’s someone in the front seat, and I won’t talk about how Porsche uses the car’s front camera to alter its regenerative braking strategy.

I won’t talk about the new three-chamber air suspension, the 82-liter frunk, the electronically adjustable sway bar that can allegedly keep body roll at zero degrees while blasting around corners, the three-valve air suspension, the tungsten carbide-coated brake rotors (variants of these last three are used in other Porsches), or the special low rolling resistance tires.

No, instead I’ll say this: I think some people may be disappointed that the Taycan’s max range is lower than the Tesla Model S’s, or that its claimed zero to 60 mph time isn’t quicker, or that it doesn’t come with Tesla’s supercharger network, and that it starts (at least for now) at $150,000—70 grand above even the Model S’s base price.

But looking at this car from an engineering standpoint, it looks to me like an extremely well-thought-out package. This is not just a Panamera stuffed with batteries.

It may not be as revolutionary as the Tesla Model S was when it debuted (the two actually share quite a few design elements), and it may not quite match the S on paper, but that’s just a statement of just how compelling of a car Tesla has built.

That said, Tesla has had some issues with prolonged track driving in the past, and it’s in this area that sports car maker Porsche says it’s put lots of focus. It’s meant to be more of a track car than the Tesla is, in theory.

Elon Musk tweeted that a Model S is headed to the Nürburgring next week. The results of that, if they’re truly objective, could provide much-needed insight into just how impressive the Taycan’s really is or isn’t.

Update, September 6, 2019, 5 P.M. ET: This story has been updated with Porsche’s answers to follow-up questions.

Update, September 7, 2019, 6:45 A.M. ET: This story originally said thermal limitations of induction motors result from the fact that current is required in the stator. I meant to write “rotor.”